Craft

December 2, 2011 at 4:35 PM by Dr. Drang

Generally speaking, I’m in favor of celebrating the spirit of amateurism; that we should make and do things for ourselves rather than always relying professionals and retailers. Even if our results aren’t perfect, the skills we develop in doing for ourselves are important in making us well-rounded humans. I’m no fan of Robert Heinlein’s politics, but this aphorism from the Notebooks of Lazarus Long has always resonated with me:

A human being should be able to change a diaper, plan an invasion, butcher a hog, conn a ship, design a building, write a sonnet, balance accounts, build a wall, set a bone, comfort the dying, take orders, give orders, cooperate, act alone, solve equations, analyze a new problem, pitch manure, program a computer, cook a tasty meal, fight efficiently, die gallantly. Specialization is for insects.

The scripting posts I publish here are a reflection of that spirit. I’m not a professional programmer, and I’m sure that shows, but I enjoy programming and try to demonstrate competence in my scripts. I hope that shows, too.

So I’m bothered by my reaction to the “maker” culture that’s extolled on Boing Boing and in the Make and Craft magazines and websites. I should be nodding my head in agreement, but I grind my teeth.

Part of my reaction comes from the hipster gloss that’s put on what is nothing more than a set of old-fashioned do-it-yourself articles. Building a bookshelf isn’t edgy or subversive, no matter how many tattoos and piercings the builder has. At heart, it’s the same project I used to read about in my Dad’s Popular Mechanics.

Actually, too often it’s not the same project, and that’s my other complaint. The old DIY articles didn’t equate amateur with incompetent. The project might be easy or it might be hard, but the goal was to produce something decent and useful and to gain some skill along the way. Many “maker” projects display no interest in skills or quality.

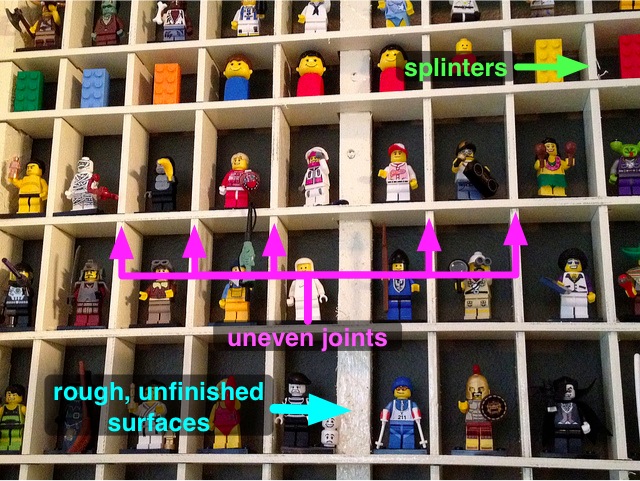

The project that set me off is this one, currently featured on the Craft website and linked to a couple of days ago on Boing Boing. It’s a display case for Lego minifigs, a simple project that could be a fun addition to a kid’s room if it were executed well. It’s not.

(Before I get into the criticism, let me start by saying that I really don’t want to be mean to the people who made this case. My beef isn’t with them; it’s with the Craft/Make/Boing Boingers who’ve decided to hold this project up as an exemplar.)

The case is made from a 1×2 pine frame with luan shelves and dividers. The pieces are put together with slotted joints cut on a table saw. From the very first photo in the article, which shows the finished case, we can see there are problems.

The luan splintered a bit as it was cut. Not unusual, and not a big problem if you clean the damned splinters off the piece before you paint it. Honestly, who paints a piece of wood without picking the splinters off first?

The same sort of person, apparently, who thinks its OK to paint a rough, stud grade 1×2 with deep mill marks still on the surface. This isn’t the kind of wood typically used out in the open—there are better grades of pine for finish work—but if you want to use it you should at least sand it down before painting. Some of the pieces look like they’re growing hair. The paint ends up enhancing the mill marks, making the piece look worse, not better.

What I found most curious, though, was the uneven fit to the joints between the shelves and the dividers. Given that the slots were cut on a table saw, they should be uniform in depth, and the fit—good or bad—should be the same across all the joints. Maybe he let the pieces ride up as he pushed them over the blade, maybe he didn’t cut them to the same width in the first place, maybe he didn’t slide them together fully—whatever the reason, it’s sloppy work.

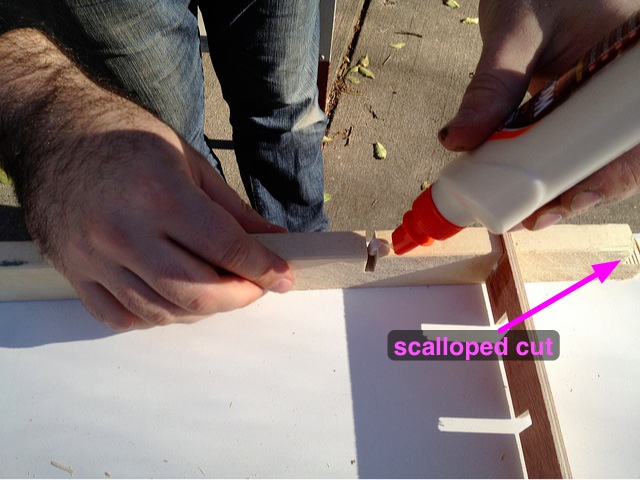

And speaking of sloppy, look at the end of this pine piece:

The scalloped surface comes from not taking the time to ensure your cuts overlap as you run the piece back and forth over the table saw blade. This is going to make the joints look like hell.

Told you.

By the way, this photo really shows how the paint brings out the mill marks in the pine.

I have other criticisms. I don’t like his choice to use a 1×1 instead of a 1×2 as the center upright in the frame. I think he should have put the joints between the shelves and the frame on the back side of the case instead of the front. But those kinds of mistakes are easy to make the first time you do a project. It’s the poor workmanship on the joints and the inexplicable failure to sand and clean up the surfaces before painting that really bother me. There is no craftsmanship to this craft.

So why is it featured, without apologies, on the website of a magazine named Craft? There is, of course, the need to feed the beast. New articles drive page views and page views are paramount. But I think the deeper problem is that the editorial oversight is done by people who don’t appreciate the time and effort it takes to develop actual skills. For them, this “maker” thing is just another topic to write and speak about for a few years, while they wait to move on to the next meme. They promote mediocrity instead of craftsmanship because they don’t know the difference.